Engineered by Cyclists

Every Rivelo product begins with a real-world need — felt on the road, not in a boardroom. Informed by experienced cyclists and shaped through a rigorous development process, our kit is built to perform where it matters most: on the ride.

So, how do we go...

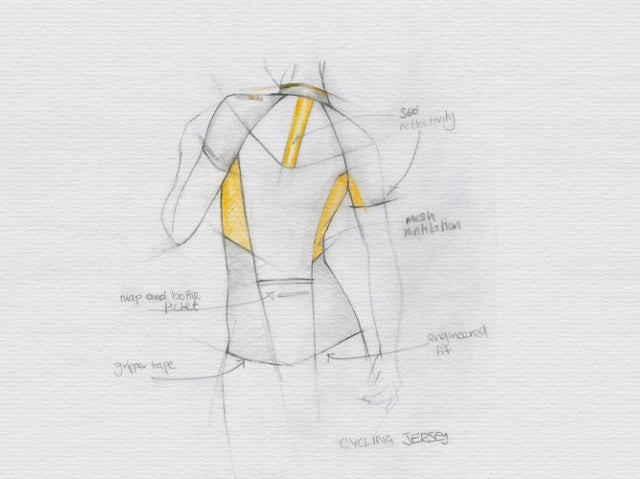

From this

To this?

What begins as a concept on paper is shaped through technical design, lab testing, and real-world riding. From the first stitch to final fit, every decision is made with the demands of the road in mind.

Our Process

-

1

Trend & market research

We analyse global cycling trends, emerging fabric technologies, and rider feedback to define clear performance goals — before a single sketch is drawn.

-

2

Technical development

From detailed tech packs to lab-dipped trims, each style is developed with mill-level precision, ensuring consistency from concept to production.

-

3

Prototyping & testing

Multiple prototypes are rider-tested across terrains and conditions — with detailed feedback captured on fit, function, and finishing.

-

4

Final validation

Pre-production samples are reviewed for performance, fit, and construction before being used in our campaign photography — and on the road.

Case study: The race range

For our Race range, we partnered with one of Italy’s most respected performance factories to push the limits of precision, fit, and rider feedback. Every detail — from pad selection to panel placement — was interrogated and refined across multiple development stages.

-

Pad selection

We worked with Cytech Elastic Interface in Italy to test chamois options directly — narrowing to three prototypes, tested by endurance riders over hundreds of kilometres.

-

Prototype wear testing

We evaluated pad density, moisture control, brace strap tension, laser-cut venting, and gripper placement — with feedback recorded after each ride.

-

Refinement

Small details made a big difference — and final adjustments included foam reshaping, repositioned vents, and updated stitching techniques to improve long-ride comfort.

This extensive process lead to a bib short that delivers high-output performance and long-distance comfort, built through collaboration and obsessive attention to detail.

Why it matters

Our design ethos is simple: performance, without compromise. For the long climbs, the hard miles, and the moments where your kit should do exactly what it's supposed to. Every detail is tested, refined, and proven on the road — so it’s ready when you are.